EN10219 S235JR Lub Raj Mis Plaub Thiab Lub Raj Mis Plaub Hollow

| yam khoom | Cov Yeeb Nkab Hlau Carbon |

| Qhov chaw keeb kwm | Tuam Tshoj |

| Lub Npe Hom | Rau hlau |

| Daim Ntawv Thov | Cov Yeeb Nkab Kua, Cov Yeeb Nkab Boiler, Cov Yeeb Nkab Tho, Cov Yeeb Nkab Hydraulic, Cov Yeeb Nkab Roj, Cov Yeeb Nkab Roj, Cov Yeeb Nkab Tshuaj Chiv, Cov Yeeb Nkab Qauv, Lwm Yam |

| Cov hlau los yog tsis | Yog Alloy |

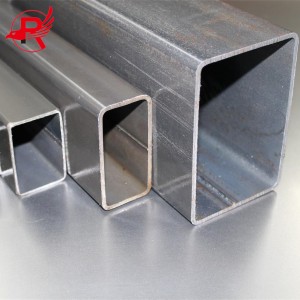

| Cov Duab Seem | Lub raj plaub fab / lub duab plaub fab |

| Cov Yeeb Nkab Tshwj Xeeb | Cov Yeeb Nkab API, Lwm Yam, Cov Yeeb Nkab EMT, Cov Yeeb Nkab Phab Ntsa tuab |

| Qhov tuab | 0.1-10 hli |

| Tus Qauv | GB |

| Ntev | 12M, 6m |

| Daim Ntawv Pov Thawj | API, ce, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, JIS, GS, ISO9001 |

| Kev siv tshuab | ERW |

| Qib | Cov hlau carbon |

| Kev Kho Mob Nto | Kub dov |

| Kev kam rau siab | ±1% |

| Kev Pabcuam Ua Haujlwm | Vuam, Xuas Nrig, Txiav, Khoov, Decoiling |

| Muaj roj los yog tsis muaj roj | Tsis muaj roj |

| Kev them nqi | los ntawm qhov hnyav theoretical |

| Lub Sijhawm Xa Khoom | 8-14 hnub |

| Lub npe khoom | Cov Yeeb Nkab Carbon Steel Square / Rectangular |

| Nto | dub/pleev xim/galvanized |

| Duab | Plaub fab/Puag ncig/Zoo li |

| Kev Siv | Kev Tsim Kho |

| Qib Hlau | Q235/Q345/Q195 |

| Xim | Thawj/pleev xim/Galvanized |

| MOQ | 1ton |

| Ntim khoom | Cov ntaub thaiv |

| Cov nqe lus them nqi | 30% TT Ua Ntej + 70% Nyiaj Tshuav |

| Phab ntsa tuab | 1.0 --15 Hli |

Cov hlau carbonyog ib qho hlau-carbon alloy nrog cov pa roj carbon ntsiab lus ntawm0.0218% txog 2.11%. Kuj hu ua carbon steel. Feem ntau kuj muaj me ntsis silicon, manganese, sulfur, phosphorus. Feem ntau, cov pa roj carbon ntau dua hauv carbon steel, qhov nyuaj dua thiab lub zog siab dua, tab sis qhov plasticity qis dua.

Ms Steel Yeeb Nkabyog ib lub yeeb nkab uas muaj plaub fab lossis plaub fab, uas yog siv dav hauv kev tsim kho, tshuab, hluav taws xob, tshuaj lom neeg thiab lwm yam teb. Cov kev siv tseem ceeb ntawm cov yeeb nkab plaub fab suav nrog:

1. Kev tsim kho vaj tse: Cov raj plaub fab siv tau ua cov khoom siv thauj khoom, xws li cov qauv hlau, cov kem txhawb nqa, cov ntoo khaub lig, thiab lwm yam, thiab kuj siv tau ua cov kav dej, cov kav dej, cov kav dej ntws, thiab lwm yam.

...2. Hauv kev tsim tshuab: cov raj plaub fab siv tau ua cov khoom siv tshuab, xws li cov bearings, sliders, guide rails, thiab lwm yam; lawv kuj siv tau ua racks, tsheb frames, thiab lwm yam.

3. Lub tshav fais fab: Cov raj plaub fab siv tau ua cov tais cable, cov qhov cable, cov raj tiv thaiv cable, thiab lwm yam, thiab muaj cov yam ntxwv zoo tiv thaiv xeb, tiv thaiv dej, thiab tiv thaiv hluav taws.

4. Kev lag luam tshuaj lom neeg:Erw Carbon Steel Yeeb Nkabsiv tau ua cov kav dej rau kev thauj cov tshuaj lom neeg, xws li thauj roj, roj, dej, kua qaub thiab alkali, thiab lwm yam, thiab kuj siv tau ua cov khoom siv tshuaj lom neeg, xws li reactors, cov khoom hloov pauv cua sov, thiab lwm yam.

Lus Cim:

1. Dawb kev kuaj mob,100%kev lees paub zoo tom qab muag, thiabkev txhawb nqa rau txhua txoj kev them nyiaj;

2. Tag nrho lwm yam lus qhia ntawmcov kav hlau carbontuaj yeem muab tau raws li koj xav tau (OEM thiab ODM)! Koj yuav tau txais tus nqi ex Hoobkas los ntawm Royal Group.

3. Kev ua haujlwmlkev pab tshuaj xyuas cov khoom,kev txaus siab ntawm cov neeg siv khoom siab.

4. Lub voj voog tsim khoom luv luv, thiab80% ntawm cov xaj yuav raug xa ua ntej.

5. Cov duab kos yog zais cia thiab txhua yam yog rau lub hom phiaj ntawm cov neeg siv khoom.

1. Cov Kev Cai: cov ntaub ntawv lossis cov duab kos

2. Kev lees paub ntawm tus muag khoom: kev lees paub tus qauv khoom

3. Paub meej tias kev hloov kho: paub meej tias lub sijhawm them nyiaj thiab lub sijhawm tsim khoom (them nyiaj tso cia)

4. Kev tsim khoom raws li qhov xav tau: tos kom tau txais daim ntawv lees paub

5. Paub meej tias tus me nyuam: them tus nqi seem thiab xa khoom

6. Paub meej tias tau txais daim ntawv txais nyiaj

Cov kev ceev faj rau kev ntim khoom thiab kev thauj mus los ntawm cov kav hlau carbon

1. Cov kav dej hlau carbon yuav tsum tau tiv thaiv los ntawm kev puas tsuaj los ntawm kev sib tsoo, extrusion thiab txiav thaum lub sijhawm thauj mus los, khaws cia thiab siv.

2. Thaum sivCov Yeeb Nkab Hlau Carbon, koj yuav tsum ua raws li cov txheej txheem kev nyab xeeb thiab ua tib zoo saib xyuas kom tsis txhob muaj kev tawg, hluav taws, lom thiab lwm yam xwm txheej.

3. Thaum siv, cov kav hlau carbon yuav tsum tsis txhob kov cov kub siab, cov xov xwm corrosive, thiab lwm yam. Yog tias siv rau hauv cov chaw no, cov kav hlau carbon ua los ntawm cov khoom siv tshwj xeeb xws li kev tiv taus kub siab thiab kev tiv taus corrosion yuav tsum tau xaiv.

4. Thaum xaiv cov kav hlau carbon, cov kav hlau carbon ntawm cov ntaub ntawv tsim nyog thiab cov lus qhia yuav tsum tau xaiv raws li kev txiav txim siab dav dav xws li kev siv ib puag ncig, cov khoom nruab nrab, siab, kub thiab lwm yam.

5. Ua ntej siv cov kav hlau carbon, yuav tsum tau kuaj xyuas thiab sim kom paub tseeb tias lawv qhov zoo ua tau raws li qhov yuav tsum tau ua.

Kev Thauj Mus Los:Qhia (Xa Khoom Qauv), Huab Cua, Tsheb Ciav Hlau, Av, Kev Thauj Khoom Hiav Txwv (FCL lossis LCL lossis Ntau)

Cov Kev Pabcuam

Peb Tshwj Xeeb Hauv Kev Ua Khoom Siv Tshwj Xeeb.

Peb pab neeg uas muaj kev paub dhau los yuav txiav, ua kom zoo nkauj thiab vuam cov khoom raws li koj cov lus qhia. Peb yog ib qho chaw pabcuam ib zaug xwb: Txiav txim siab cov khoom koj xav tau, kom lawv kho kom haum rau koj cov lus qhia, thiab tau txais kev xa khoom sai thiab dawb. Peb lub hom phiaj yog kom txo qis kev ua haujlwm rau koj - txuag koj lub sijhawm thiab nyiaj txiag.

Kev txiav, Shearing & Kev txiav nplaim taws

Peb muaj peb lub tshuab txiav hlau bandsaws nyob rau ntawm qhov chaw uas muaj peev xwm txiav miter. Peb txiav phaj hluav taws ⅜" tuab txog 4½", thiab peb lub Cincinnati Shear muaj peev xwm txiav daim ntawv nyias li 22 gauge thiab hnyav li ¼” square thiab raug. Yog tias koj xav tau cov ntaub ntawv txiav sai thiab raug, peb muab kev pabcuam tib hnub.

Kev vuam

Peb lub tshuab Lincoln 255 MIG Vuam Tshuab tso cai rau peb cov neeg vuam uas muaj kev paub txog vuam txhua yam ncej tsev lossis lwm yam hlau uas koj xav tau.

Kev Ntaus Qhov

Peb tshwj xeeb hauv kev tsim cov phaj hlau flitch. Peb pab neeg tuaj yeem tsim cov qhov me me li ⅛" txoj kab uas hla thiab loj li 4¼" txoj kab uas hla. Peb muaj Hougen thiab Milwaukee magnetic drill presses, manual punches thiab ironworkers, thiab automatic CNC punches thiab drill presses.

Kev cog lus ua haujlwm rau lwm tus

Yog tias tsim nyog, peb yuav ua haujlwm nrog ib tus ntawm peb cov neeg koom tes thoob plaws lub tebchaws los xa cov khoom zoo tshaj plaws thiab pheej yig rau koj. Peb txoj kev koom tes ua kom ntseeg tau tias koj daim ntawv xaj raug tswj hwm zoo los ntawm cov kws tshaj lij tshaj plaws hauv kev lag luam.

Q: Puas yog lub chaw tsim khoom ua?

A: Yog, peb yog cov chaw tsim khoom. Peb muaj peb lub Hoobkas nyob hauv Tianjin City, Suav.

Q: Kuv puas tuaj yeem muaj kev txiav txim sim tsuas yog ob peb tons xwb?

A: Tau kawg. Peb tuaj yeem xa cov khoom thauj rau koj nrog LCL servivece. (Tsawg dua lub thawv thauj khoom)

Q: Yog tias cov qauv dawb?

A: Qauv pub dawb, tab sis tus neeg yuav khoom them rau cov khoom thauj.

Q: Koj puas yog tus neeg muag khoom kub thiab ua kev lag luam lav?

A: Peb xya xyoo tus neeg muag khoom kub thiab lees txais kev lees paub kev lag luam.