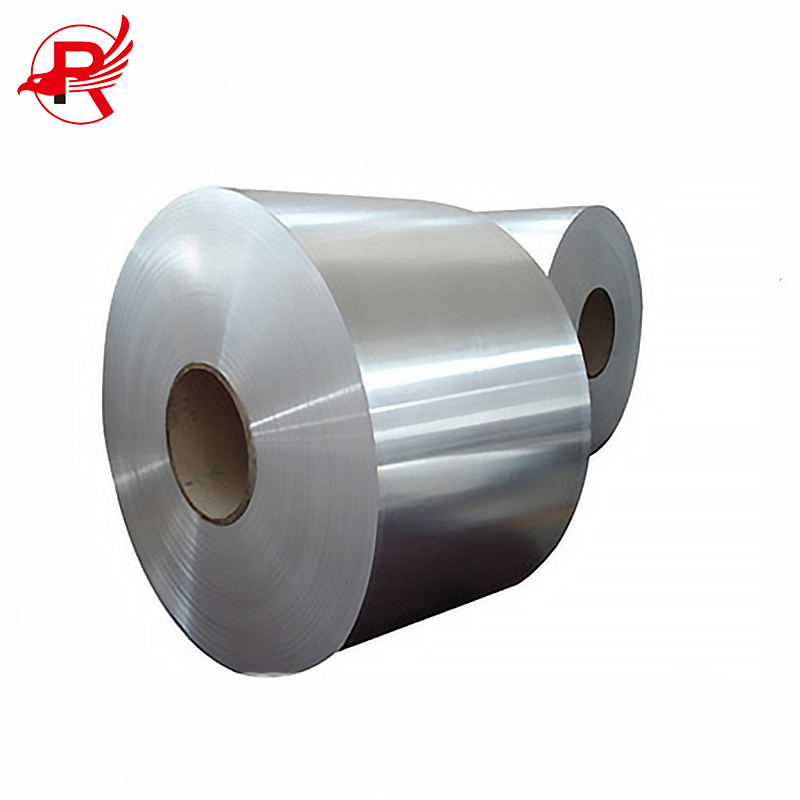

Txheej 1050 Dov Txhuas Txhuas Coil

| 1) 1000 Series Alloy (Feem ntau hu ua kev lag luam txhuas ntshiab, Al> 99.0%) | |

| Kev dawb huv | 1050 1050A 1060 1070 1100 |

| Kev chim siab | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/ H26/H36 H18/H28/H38 H114/H194, thiab lwm yam. |

| Cov Lus Qhia Tshwj Xeeb | Thickness≤30mm; Dav≤2600mm; Ntev≤16000mm LOS YOG Coil (C) |

| Daim Ntawv Thov | Lub hau npog, Cov khoom siv rau kev lag luam, Chaw cia khoom, Txhua hom thawv, thiab lwm yam. |

| Feature | Lub hau Shigh conductivity, kev ua haujlwm zoo corrosion resistant, siab latent heat ntawm kev yaj, kev cuam tshuam siab, cov cuab yeej vuam zoo, lub zog qis, thiab tsis tsim nyog rau kev kho cua sov. |

| 2) 3000 Series Alloy (Feem ntau hu ua Al-Mn Alloy, Mn yog siv ua lub ntsiab alloy) | |

| Cov hlau nplaum | 3003 3004 3005 3102 3105 |

| Kev chim siab | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/ H36 H18/H28/H38 H114/H194, thiab lwm yam. |

| Cov Lus Qhia Tshwj Xeeb | Thickness≤30mm; Dav≤2200mm Ntev≤12000mm LOS YOG Coil (C) |

| Daim Ntawv Thov | Kho kom zoo nkauj, lub tshuab cua sov, phab ntsa sab nraud, chaw cia khoom, ntawv rau kev tsim kho, thiab lwm yam. |

| Feature | Zoo tiv taus xeb, tsis haum rau kev kho cua sov, zoo tiv taus corrosion kev ua tau zoo, cov cuab yeej vuam zoo, cov khoom yas zoo, lub zog tsawg tab sis tsim nyog rau kev ua haujlwm txias hardening |

| 3) 5000 Series Alloy (Feem ntau hu ua Al-Mg Alloy, Mg yog siv ua lub ntsiab alloy) | |

| Cov hlau nplaum | 5005 5052 5083 5086 5182 5754 5154 5454 5A05 5A06 |

| Kev chim siab | O/H111 H112 H116/H321 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38 H114/H194, thiab lwm yam. |

| Cov Lus Qhia Tshwj Xeeb | Thickness≤170mm; Dav≤2200mm; Ntev≤12000mm |

| Daim Ntawv Thov | Phaj Qib Marine, Ring-Rub Qhov Kawg Taub Hau Tshuag, Ring-Rub Tshuag, Tsheb Cov Ntawv Qhia Lub Cev, Lub Tsheb Sab Hauv Board, Lub Npog Tiv Thaiv Ntawm Cav. |

| Feature | Tag nrho cov txiaj ntsig ntawm cov hlau txhuas ib txwm muaj, lub zog tensile siab & lub zog tawm los, kev ua haujlwm zoo tiv taus corrosion, zoo welding cuab yeej, zoo qaug zog lub zog, thiab tsim nyog rau anodizing. |

| 4) 6000 Series Alloy (Feem ntau hu ua Al-Mg-Si Alloy, Mg thiab Si yog siv ua cov ntsiab lus tseem ceeb) | |

| Cov hlau nplaum | 6061 6063 6082 |

| Kev chim siab | OF, thiab lwm yam. |

| Cov Lus Qhia Tshwj Xeeb | Thickness≤170mm; Dav≤2200mm; Ntev≤12000mm |

| Daim Ntawv Thov | Tsheb, Aluminium Rau Aviation, Industrial Mould, Mechanical Components, Kev Thauj Mus Los Nkoj, Cov Khoom Siv Semiconductor, thiab lwm yam |

| Feature | Kev ua haujlwm zoo tiv taus corrosion, zoo vuam khoom, zoo oxidability, yooj yim rau tshuaj tsuag-ua tiav, zoo oxidation xim, zoo machinability. |

1. Nws yogPrepainted Gi Steel Coilsiv ua cov khoom siv kho kom zoo nkauj.

2. Siv los ua cov profile xws li qhov rooj thiab qhov rai thav duab thiab qhov rai sashes

3. Hauv kev lag luam kev tsim kho, nws tuaj yeem siv ua cov ntaub ntawv tsim kho, cov khoom siv kho tshuab thiab cov khoom dai kom zoo nkauj.

4. Siv ua tus neeg xyuas pib los ua hlau dag.

5. Nws tuaj yeem ua rau hauv cov pas nrig thiab cov qhov tubular, uas yog siv dav hauv kev lag luam twj paj nruag.

6. Nws siv tau ua precision casting aluminium alloy ingot.

7. Nws siv tau los ua cov roj tsheb.

8. Siv tau ua cov khoom pwm.

9. Siv tau rau hauv kev lag luam tshuaj lom neeg.

10. Siv tau rau hauv kev lag luam tshuab.

Lus Cim:

1. Kev kuaj dawb, 100% kev lees paub zoo tom qab muag, Txhawb nqa txhua txoj kev them nqi;

2. Tag nrho lwm yam lus qhia ntawm cov kav dej hlau carbon puag ncig muaj raws li koj xav tau (OEM & ODM)! Tus nqi Hoobkas koj yuav tau txais los ntawm ROYAL GROUP.

| DAV (MM) | (hli) | (hli) | (hli) | (hli) | (hli) |

| 1000 | 1 | 2 | 3 | 4 | Lwm yam |

| 1219 | 1 | 2 | 3 | 4 | Lwm yam |

| 1220 | 1 | 2 | 3 | 4 | Lwm yam |

| 1500 xyoo | 1 | 2 | 3 | 4 | Lwm yam |

| 2000 xyoo | 1 | 2 | 3 | 4 | Lwm yam |

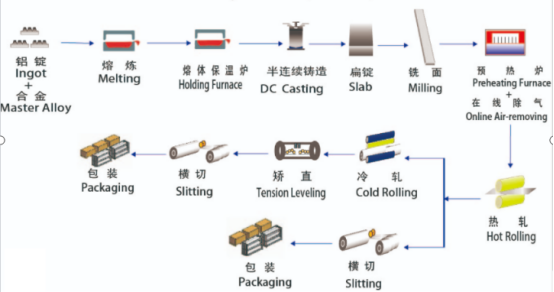

Cov txheej txheem tsim khoom ntawmHlau Coil PPGI: cov txhuas ingots raug muab tso rau hauv lub cub tawg smelting, hlawv thiab yaj nrog cov roj av, slag raug tshem tawm thiab pov tseg raug tshem tawm, alloy raug teeb tsa, lub cub tawg qhia raug xa mus rau lub cub tawg tuav, dej txhuas raug muab tso rau hauv, dhau los ntawm lub nozzle tuag casting, dov thiab dov, thiab dov thiab dov dov, annealing, hla-txiav mus rau qhov loj me xav tau, engraving raws li cov duab kos, folding, reinforcing ribs, vuam, sib tsoo, txau, tshuaj xyuas, pasting ntawm zaj duab xis tiv thaiv, cua cushion zaj duab xis, ntim khoom, thauj khoom thiab xa khoom.

Feem ntau cov ntim khoom yog liab qab, hlau xaim khi, muaj zog heev.

Yog tias koj muaj cov kev xav tau tshwj xeeb, koj tuaj yeem siv cov ntim khoom tsis xeb, thiab zoo nkauj dua.

Kev Thauj Mus Los:Qhia (Xa Khoom Qauv), Huab Cua, Tsheb Ciav Hlau, Av, Kev Thauj Khoom Hiav Txwv (FCL lossis LCL lossis Ntau)

Q: Puas yog lub chaw tsim khoom ua?

A: Yog, peb yog cov chaw tsim khoom. Peb muaj peb lub Hoobkas nyob hauv Tianjin City, Suav teb. Dhau li ntawd, peb koom tes nrog ntau lub xeev cov lag luam, xws li BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, thiab lwm yam.

Q: Kuv puas tuaj yeem muaj kev txiav txim sim tsuas yog ob peb tons xwb?

A: Tau kawg. Peb tuaj yeem xa cov khoom thauj rau koj nrog LCL servivece. (Tsawg dua lub thawv thauj khoom)

Q: Yog tias cov qauv dawb?

A: Qauv pub dawb, tab sis tus neeg yuav khoom them rau cov khoom thauj.

Q: Koj puas yog tus neeg muag khoom kub thiab ua kev lag luam lav?

A: Peb xya xyoo tus neeg muag khoom kub thiab lees txais kev lees paub kev lag luam.