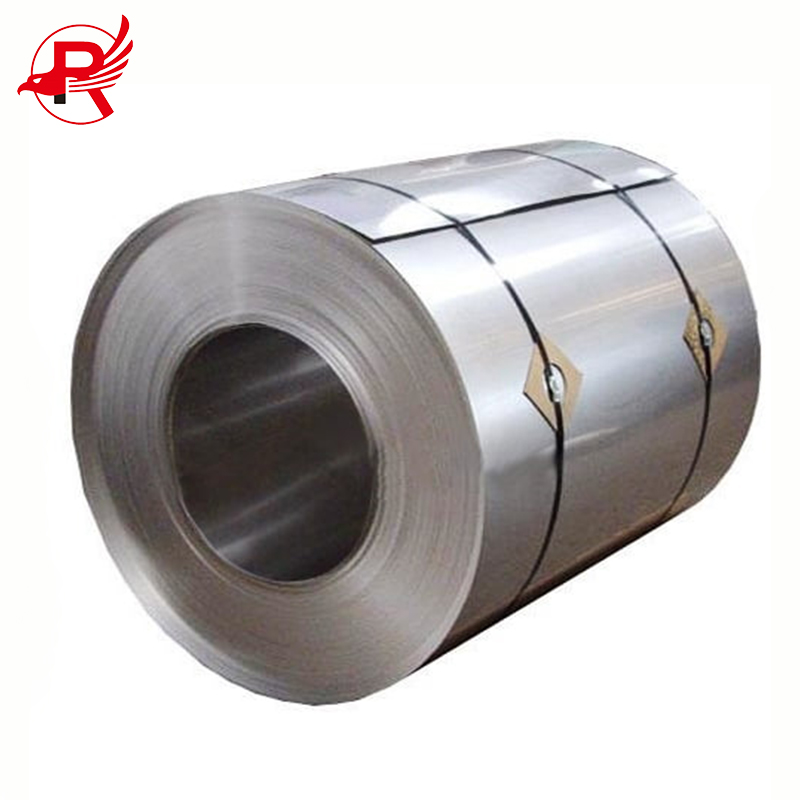

Hoobkas Suav Zoo Kub Muag Hr 630 Nqe Stainless Hlau Chev

| Lub Npe Khoom | 630 stainless hlau kauj |

| Qhov nyuaj | 190-250HV |

| Qhov tuab | 0.02 hli-6.0 hli |

| Dav | 1.0 hli-1500 hli |

| Ntug | Qhov Txiav/Mill |

| Kev kam rau siab ntau npaum li cas | ±10% |

| Daim Ntawv Core Sab Hauv Txoj Kab Uas hla | Ø500mm ntawv tub ntxhais, tshwj xeeb sab hauv txoj kab uas hla tub ntxhais thiab tsis muaj ntawv tub ntxhais ntawm cov neeg siv khoom thov |

| Qhov Chaw Tiav | NO.1/2B/2D/BA/HL/Brushed/6K/8K Daim Iav, thiab lwm yam |

| Ntim Khoom | Ntoo Pallet / Ntoo Case |

| Cov nqe lus them nqi | 30% TT tso nyiaj thiab 70% tshuav nyiaj ua ntej xa khoom, 100% LC thaum pom |

| Lub Sijhawm Xa Khoom | 7-15 hnub ua haujlwm |

| MOQ | 200Kgs |

| Chaw nres nkoj xa khoom | Shanghai / Ningbo chaw nres nkoj |

| Qauv | Cov qauv ntawm 630 stainless hlau kauj yog muaj |

630 yog cov hlau tsis muaj carbon uas tsis muaj zog thiab muaj zog heev. Nws yog cov khoom siv zoo rau ntau yam kev siv xws li cov khoom siv ua zaub mov thiab cov khoom siv ua tshuaj.

Cov hauv qab no yog cov npe ntawm qee cov ntawv thov ntau dua rau 630 stainless hlau coils:

1. Cov Khoom Siv Ua Khoom Noj & Cov Khoom Siv Ua Tshuaj

2. Kev Lag Luam Roj thiab Roj Av

3. Cov Ntawv Thov Marine

Lus Cim:

1. Kev kuaj dawb, 100% kev lees paub zoo tom qab muag, Txhawb nqa txhua txoj kev them nqi;

2. Tag nrho lwm yam lus qhia ntawm cov kav dej hlau carbon puag ncig muaj raws li koj xav tau (OEM & ODM)! Tus nqi Hoobkas koj yuav tau txais los ntawm ROYAL GROUP.

Cov Tshuaj Lom Zem ntawm Cov Hlau Stainless Steel Chev

| Cov Tshuaj Muaj pes tsawg leeg% | ||||||||

| Qib | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 | ≤0.75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0.15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0.15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0.07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0. 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Los ntawm ntau txoj kev ua tiav ntawm kev dov txias thiab kev ua dua tshiab tom qab dov, qhov tiav ntawm 630 stainless hlau coils tuaj yeem muaj ntau hom.

Cov txheej txheem ua tiav ntawm cov hlau tsis xeb muaj NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR nyuaj, Rerolled ci 2H, polishing ci thiab lwm yam tiav nto, thiab lwm yam.

Cia peb saib ze dua ntawm kev kho qhov chaw ntawm cov hlau tsis xeb.

1. Pickling: Kauj ruam thawj zaug hauv kev kho qhov chaw ntawm cov hlau tsis xeb yog pickling. Pickling yog cov txheej txheem ntawm kev kho qhov chaw ntawm cov khoom siv nrog cov kua qaub kom tshem tawm cov pa phem xws li xeb, nplai thiab oxides. Cov txheej txheem no suav nrog kev muab lub kauj tso rau hauv da dej ntawm hydrochloric lossis sulfuric acid, uas yaj cov khoom tsis huv thiab ua kom qhov chaw huv.

2. Dov: Tom qab cov txheej txheem pickling, cov hlau stainless hlau raug dov kom ua rau qhov tuab thiab qhov tiaj tus sib npaug. Cov txheej txheem cuam tshuam nrog kev hla lub kauj los ntawm ntau lub rollers uas nias thiab ua cov khoom. Lub roller tuaj yeem hloov kho kom tsim cov tiav sib txawv, los ntawm matte mus rau glossy.

3. Kev Ua Kub: Tom ntej no, cov hlau stainless hlau raug ua kom kub thaum lub sijhawm kho cua sov. Kev ua kub pab ua kom cov khoom mos thiab ua rau nws yooj yim dua, ua rau nws yooj yim dua los tsim cov kauj lossis lwm yam duab. Cov txheej txheem ua kub suav nrog kev ua kom lub kauj kub mus rau qhov kub siab thiab tom qab ntawd txias nws maj mam dhau sijhawm.

4. Kev Sib Tsoo: Tom qab cov hlau stainless hlau raug annealed, nws yog av kom tsim tau qhov chaw du thiab ci ntsa iab. Cov kauj ruam no suav nrog kev siv cov cuab yeej abrasive los tshem tawm cov burrs lossis qhov tsis zoo thiab tsim kom muaj qhov chaw sib npaug. Qhov no ua rau muaj qhov chaw sib npaug thiab ci ntsa iab.

5. Kev Txhuam: Thaum kawg, cov hlau stainless hlau yog txhuam kom zoo nkauj dua. Kev txhuam yog ib qho txheej txheem kho qhov chaw uas muaj kev txhuam cov khoom siv nrog cov khoom sib xyaw zoo kom tsim tau qhov ci ntsa iab thiab cuam tshuam. Cov kauj ruam no ua kom cov hlau stainless zoo nkauj dua thiab tsim kom muaj kev cuam tshuam specular.

Cov txheej txheem ntau lawm ntawm cov hlau tsis xeb yog: kev npaj cov khoom siv raw - annealing thiab pickling - (intermediate grinding) - dov - intermediate annealing - pickling - dov - annealing - pickling - leveling (cov khoom tiav lawm grinding thiab polishing) - txiav, ntim thiab khaws cia.

tus qauv ntim khoom hiav txwv ntawm 630 stainless hlau kauj

Txheem export hiav txwv ntim:

Daim Ntawv Tsis Muaj Dej Winding + PVC Zaj Duab Xis + Strap Banding + Ntoo Pallet lossis Ntoo Case;

Kev ntim khoom raws li koj qhov kev thov (Logo lossis lwm yam ntsiab lus lees txais kom luam tawm ntawm lub ntim);

Lwm cov ntim khoom tshwj xeeb yuav raug tsim los ntawm cov neeg siv khoom thov;

Kev Thauj Mus Los:Qhia (Xa Khoom Qauv), Huab Cua, Tsheb Ciav Hlau, Av, Kev Thauj Khoom Hiav Txwv (FCL lossis LCL lossis Ntau)

Q: Puas yog lub chaw tsim khoom ua?

A: Yog, peb yog cov chaw tsim khoom. Peb muaj peb lub Hoobkas nyob hauv Tianjin City, Suav teb. Dhau li ntawd, peb koom tes nrog ntau lub xeev cov lag luam, xws li BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, thiab lwm yam.

Q: Kuv puas tuaj yeem muaj kev txiav txim sim tsuas yog ob peb tons xwb?

A: Tau kawg. Peb tuaj yeem xa cov khoom thauj rau koj nrog LCL servivece. (Tsawg dua lub thawv thauj khoom)

Q: Yog tias cov qauv dawb?

A: Qauv pub dawb, tab sis tus neeg yuav khoom them rau cov khoom thauj.

Q: Koj puas yog tus neeg muag khoom kub thiab ua kev lag luam lav?

A: Peb xya xyoo tus neeg muag khoom kub thiab lees txais kev lees paub kev lag luam.