Tus nqi zoo tshaj plaws ASTM A312 304 304L 316LStainless Steel Yeeb Nkab

| Lub Npe Khoom | Cov yeeb nkab stainless hlau |

| Tus Qauv | ASTM AISI DIN, EN, GB, JIS |

| Qib Hlau

| 200 Series: 201,202 |

| 300 Series: 301,304,304L, 316,316L, 316Ti, 317L, 321,309s, 310s | |

| 400 Series: 409L, 410, 410s, 420j1, 420j2, 430, 444, 441, 436 | |

| Duplex Hlau: 904L, 2205,2507,2101,2520,2304 | |

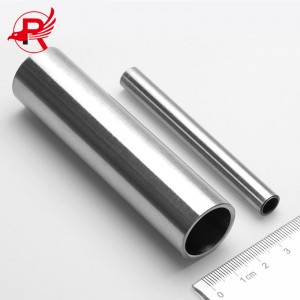

| Txoj kab uas hla sab nraud | 6-2500mm (raws li xav tau) |

| Qhov tuab | 0.3mm-150mm (raws li xav tau) |

| Ntev | 2000mm/2500mm/3000mm/6000mm/12000mm (raws li xav tau) |

| Kev siv tshuab | Tsis muaj qhov sib txuas |

| Nto | Daim Iav No.1 2B BA 6K 8K Daim Iav No.4 HL |

| Kev kam rau siab | ±1% |

| Cov nqe lus | FOB, CFR, CIF |

Cov yeeb nkab hlau tsis xeb yog ib hom hlau hollow ntev puag ncig, uas feem ntau yog siv rau hauv cov kav dej thauj mus los hauv kev lag luam xws li roj av, kev lag luam tshuaj lom neeg, kev kho mob, khoom noj khoom haus, kev lag luam sib zog, cov cuab yeej siv tshuab, thiab lwm yam, nrog rau cov khoom siv kho tshuab. Tsis tas li ntawd, thaum lub zog khoov thiab torsional zoo ib yam, qhov hnyav sib dua, yog li nws kuj siv dav hauv kev tsim cov khoom siv kho tshuab thiab cov qauv tsim kho. Kuj tseem siv ua rooj tog thiab khoom siv hauv chav ua noj, thiab lwm yam.

Lus Cim:

1. Kev kuaj dawb, 100% kev lees paub zoo tom qab muag, Txhawb nqa txhua txoj kev them nqi;

2. Tag nrho lwm yam lus qhia ntawm cov kav dej hlau carbon puag ncig muaj raws li koj xav tau (OEM & ODM)! Tus nqi Hoobkas koj yuav tau txais los ntawm ROYAL GROUP.

Cov Tshuaj Lom Zem ntawm Cov Yeeb Nkab Hlau Stainless

| Cov Tshuaj Muaj pes tsawg leeg% | ||||||||

| Qib | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 | ≤0.75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0.15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0.15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0.07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0. 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Los ntawm ntau txoj kev ua tiav ntawm kev dov txias thiab kev ua tiav ntawm qhov chaw tom qab dov, qhov chaw tiav ntawm cov hlau tsis xeblub bars muaj peev xwm muaj ntau hom sib txawv.

Cov txheej txheem ua tiav ntawm cov yeeb nkab tsis xeb muaj NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR nyuaj, Rerolled ci 2H, polishing ci thiab lwm yam tiav qhov chaw, thiab lwm yam.

NO.1: Tus naj npawb 1 nto yog qhov chaw tau los ntawm kev kho cua sov thiab pickling tom qab kub dov ntawm cov yeeb nkab stainless hlau. Nws yog los tshem tawm cov nplai dub oxide tsim tawm thaum lub sijhawm kub dov thiab kho cua sov los ntawm pickling lossis cov txheej txheem kho zoo sib xws. Qhov no yog Tus naj npawb 1 nto ua tiav. Tus naj npawb 1 nto yog silvery dawb thiab matt. Feem ntau siv rau hauv kev lag luam tiv taus cua sov thiab corrosion-resistant uas tsis xav tau qhov ci ntsa iab, xws li kev lag luam cawv, kev lag luam tshuaj lom neeg thiab cov thawv loj.

2B: Qhov chaw ntawm 2B txawv ntawm qhov chaw 2D vim nws tau du nrog lub roller du, yog li nws ci dua li qhov chaw 2D. Qhov roughness ntawm qhov chaw Ra ntsuas los ntawm lub cuab yeej yog 0.1 ~ 0.5 μm, uas yog hom kev ua tiav feem ntau. Hom hlau stainless hlau no yog qhov siv tau ntau yam, haum rau cov hom phiaj dav dav, uas siv dav hauv tshuaj lom neeg, ntawv, roj av, kev kho mob thiab lwm yam lag luam, thiab kuj tseem siv tau ua phab ntsa thaiv tsev.

TR Hard Finish: TR stainless hlau kuj hu ua hlau tawv. Nws cov qib hlau sawv cev yog 304 thiab 301, lawv siv rau cov khoom uas xav tau lub zog siab thiab tawv, xws li tsheb ciav hlau, siv txoj siv conveyor, springs thiab gaskets. Lub hauv paus ntsiab lus yog siv cov yam ntxwv ua haujlwm tawv ntawm austenitic stainless hlau los ua kom lub zog thiab tawv ntawm lub phaj hlau los ntawm cov txheej txheem ua haujlwm txias xws li dov. Cov khoom siv tawv siv ob peb feem pua mus rau ntau kaum feem pua ntawm cov dov me me los hloov qhov tiaj tiaj ntawm 2B puag nto, thiab tsis muaj annealing tom qab dov. Yog li ntawd, TR tawv nto ntawm cov khoom siv tawv yog dov tom qab txias dov nto.

Rov dov dua Ci 2H: Tom qab cov txheej txheem dov. cov yeeb nkab stainless hlau yuav raug ua tiav ci annealing. Cov yeeb nkab tuaj yeem txias sai los ntawm cov kab annealing tas mus li. Qhov ceev ntawm cov yeeb nkab stainless hlau ntawm kab yog nyob ib puag ncig 60m ~ 80m / feeb. Tom qab cov kauj ruam no, qhov tiav ntawm qhov chaw yuav yog 2H rov dov dua ci.

No.4: Qhov chaw ntawm No. 4 yog qhov chaw ci ntsa iab zoo nkauj uas ci dua li qhov chaw ntawm No. 3. Nws kuj tau txais los ntawm kev txhuam cov yeeb nkab stainless hlau txias-dov nrog 2 D lossis 2 B nto ua lub hauv paus thiab txhuam nrog txoj siv abrasive nrog qhov loj me ntawm 150-180 # Machined nto. Qhov roughness ntawm qhov chaw Ra ntsuas los ntawm cov cuab yeej yog 0.2 ~ 1.5μm. NO.4 nto yog siv dav hauv cov khoom siv hauv tsev noj mov thiab chav ua noj, cov khoom siv kho mob, kev kho kom zoo nkauj, thawv, thiab lwm yam.

HL: HL nto feem ntau hu ua hairline finish. Tus qauv JIS Nyiv Pooj hais tias siv 150-240 # abrasive siv los txhuam cov nto abrasive uas zoo li hairline. Hauv tus qauv GB3280 ntawm Tuam Tshoj, cov cai tsis meej. HL nto finish feem ntau yog siv rau kev kho kom zoo nkauj xws li lub tshuab nqa, cov ntaiv, thiab cov ntsej muag.

Naj Npawb 6: Qhov chaw ntawm Naj Npawb 6 yog raws li qhov chaw ntawm Naj Npawb 4 thiab ntxiv rau polished nrog Tampico txhuam lossis cov khoom siv abrasive nrog qhov loj me ntawm W63 teev los ntawm GB2477 tus qauv. Qhov chaw no muaj cov xim hlau zoo thiab kev ua haujlwm mos. Qhov kev cuam tshuam tsis muaj zog thiab tsis cuam tshuam daim duab. Vim yog qhov zoo no, nws yog qhov tsim nyog heev rau kev ua cov phab ntsa ntaub thaiv thiab cov khoom dai kom zoo nkauj, thiab kuj siv dav ua cov khoom siv hauv chav ua noj.

BA: BA yog qhov chaw tau los ntawm kev kho cua sov ci tom qab dov txias. Kev kho cua sov ci yog annealing nyob rau hauv ib puag ncig tiv thaiv uas lav tias qhov chaw tsis oxidized los khaws cia qhov ci ntawm qhov chaw txias-dov, thiab tom qab ntawd siv lub tshuab ua kom du thiab meej rau kev teeb tsa lub teeb kom txhim kho qhov ci ntawm qhov chaw. Qhov chaw no ze rau daim iav tiav, thiab qhov roughness ntawm qhov chaw Ra ntsuas los ntawm cov cuab yeej yog 0.05-0.1μm. BA nto muaj ntau yam kev siv thiab tuaj yeem siv ua cov khoom siv hauv chav ua noj, cov khoom siv hauv tsev, cov khoom siv kho mob, cov khoom siv tsheb thiab cov khoom dai kom zoo nkauj.

Naj Npawb 8: Naj Npawb 8 yog ib qho chaw ua tiav daim iav uas muaj qhov cuam tshuam siab tshaj plaws yam tsis muaj cov noob abrasive. Kev lag luam ua cov hlau stainless hlau tob kuj hu ua 8K phaj. Feem ntau, cov ntaub ntawv BA yog siv ua cov khoom siv raw rau daim iav tiav tsuas yog los ntawm kev sib tsoo thiab polishing. Tom qab daim iav tiav, qhov chaw yog kos duab, yog li nws feem ntau siv rau hauv kev kho kom zoo nkauj nkag thiab kho kom zoo nkauj sab hauv.

Cov txheej txheem tseem ceeb: cov hlau puag ncig → rov tshuaj xyuas → tev tawv → blanking → centering → cua sov → perforation → pickling → lub taub hau tiaj tus → tshuaj xyuas thiab sib tsoo → txias dov (txias kos duab) → degreasing → kho cua sov → ncaj → txiav yeeb nkab (ruaj khov-rau-ntev) → pickling / passivation → tiav cov khoom tshuaj xyuas (eddy tam sim no, ultrasonic, dej siab) → ntim khoom thiab khaws cia.

1. Kev txiav hlau puag ncig: Tom qab tau txais cov hlau puag ncig los ntawm lub tsev khaws khoom siv raw, xam qhov ntev ntawm cov hlau puag ncig raws li qhov yuav tsum tau ua ntawm cov txheej txheem, thiab kos ib txoj kab rau ntawm cov hlau puag ncig. Cov hlau raug teeb tsa raws li qib hlau, tus lej cua sov, tus lej ntau lawm thiab cov lus qhia, thiab cov kawg tau sib txawv los ntawm cov xim sib txawv.

2. Kev Nruab Nrab: Thaum nruab nrab ntawm lub tshuab drilling caj npab hla, xub nrhiav qhov chaw nruab nrab hauv ib ntu ntawm cov hlau puag ncig, xuas lub qhov qauv tawm, thiab tom qab ntawd kho nws ntsug ntawm lub rooj drilling tshuab rau kev nruab nrab. Cov kab puag ncig tom qab nruab nrab yog stacked raws li qib hlau, tus lej cua sov, kev qhia tshwj xeeb thiab tus lej ntau lawm.

3. Kev tev tawv: kev tev tawv yog ua tiav tom qab dhau qhov kev tshuaj xyuas cov khoom nkag los. Kev tev tawv suav nrog kev tev tawv ntawm lub tshuab dhos thiab kev txiav khaub zig cua. Kev tev tawv ntawm lub tshuab dhos yog ua tiav ntawm lub tshuab dhos los ntawm txoj kev ua tiav ntawm ib lub clamp thiab ib sab saum toj, thiab kev txiav khaub zig cua yog dai cov hlau puag ncig ntawm lub cuab yeej tshuab. Ua kev sib hloov.

4. Kev tshuaj xyuas qhov chaw: Kev tshuaj xyuas qhov zoo ntawm cov hlau puag ncig uas tau tev tawm lawm, thiab cov qhov tsis zoo ntawm qhov chaw uas twb muaj lawm raug cim, thiab cov neeg ua haujlwm sib tsoo yuav sib tsoo lawv kom txog thaum lawv tsim nyog. Cov hlau puag ncig uas tau dhau qhov kev tshuaj xyuas raug muab sib sau ua ke raws li qib hlau, tus lej cua sov, qhov kev qhia tshwj xeeb thiab tus lej ntau lawm.

5. Kev cua sov hlau puag ncig: Cov khoom siv cua sov hlau puag ncig suav nrog lub cub tawg uas siv roj thiab lub cub tawg uas siv roj. Lub cub tawg uas siv roj siv rau kev cua sov hauv cov pawg loj, thiab lub cub tawg uas siv roj siv rau kev cua sov hauv cov pawg me. Thaum nkag mus rau hauv lub cub tawg, cov hlau puag ncig ntawm cov qib hlau sib txawv, cov lej cua sov thiab cov lus qhia tshwj xeeb raug cais los ntawm zaj duab xis sab nraud qub. Thaum cov hlau puag ncig raug cua sov, cov neeg tig siv cov cuab yeej tshwj xeeb los tig cov hlau kom ntseeg tau tias cov hlau puag ncig raug cua sov sib npaug.

6. Kev tho qhov kub thiab txias: siv lub tshuab tho qhov thiab lub tshuab cua compressor. Raws li cov lus qhia ntawm cov hlau puag ncig uas muaj perforated, cov phaj qhia thiab cov ntsaws molybdenum raug xaiv, thiab cov hlau puag ncig uas tau cua sov raug perforated nrog lub perforator, thiab cov kav dej khib nyiab raug tho rau hauv pas dej kom txias tag nrho.

7. Kev Tshuaj Xyuas thiab Kev Sib Tsoo: Xyuas kom cov nplaim sab hauv thiab sab nraud ntawm cov yeeb nkab pov tseg du thiab du, thiab yuav tsum tsis muaj daim tawv paj, tawg, interlayers, qhov tob tob, cov cim xov loj, hlau tower, fritters, Baotou thiab sickle taub hau. Cov qhov tsis zoo ntawm cov yeeb nkab pov tseg tuaj yeem tshem tawm los ntawm txoj kev sib tsoo hauv zos. Cov yeeb nkab pov tseg uas tau dhau qhov kev tshuaj xyuas lossis cov uas tau dhau qhov kev tshuaj xyuas tom qab kho thiab sib tsoo nrog cov qhov tsis zoo me me yuav tsum tau muab cov khoom ntim los ntawm cov chaw ua haujlwm raws li qhov yuav tsum tau ua, thiab muab cov khoom ntim raws li qib hlau, tus lej cub tawg, cov lus qhia thiab cov lej ntau lawm ntawm cov yeeb nkab pov tseg.

8. Kev Ncaj: Cov kav dej khib nyiab nkag mus rau hauv lub chaw ua haujlwm perforation tau ntim ua cov pob khoom. Cov duab ntawm cov kav dej khib nyiab nkag mus yog khoov thiab yuav tsum tau ncaj. Cov khoom siv ncaj yog lub tshuab ncaj ntsug, lub tshuab ncaj kab rov tav thiab lub tshuab hydraulic ntsug (siv rau kev ncaj ua ntej thaum cov yeeb nkab hlau muaj qhov nkhaus loj). Txhawm rau tiv thaiv cov yeeb nkab hlau kom tsis txhob dhia thaum lub sijhawm ncaj, lub tes tsho nylon siv los txwv cov yeeb nkab hlau.

9. Kev txiav yeeb nkab: Raws li txoj kev npaj tsim khoom, cov yeeb nkab pov tseg uas ncaj yuav tsum tau txiav lub taub hau thiab tus tw, thiab cov khoom siv siv yog lub tshuab txiav log sib tsoo.

10. Pickling: Cov yeeb nkab hlau ncaj yuav tsum tau pickled kom tshem tawm cov nplai oxide thiab cov khoom tsis huv ntawm qhov chaw ntawm cov yeeb nkab pov tseg. Cov yeeb nkab hlau raug pickled hauv lub chaw ua haujlwm pickling, thiab cov yeeb nkab hlau maj mam hoisted rau hauv lub tank pickling rau pickling los ntawm kev tsav tsheb.

11. Kev sib tsoo, kev tshuaj xyuas endoscopy thiab kev txhuam sab hauv: cov kav hlau uas tsim nyog rau pickling nkag mus rau hauv cov txheej txheem sib tsoo sab nraud, cov kav hlau polished raug rau kev tshuaj xyuas endoscopic, thiab cov khoom tsis tsim nyog lossis cov txheej txheem nrog cov kev cai tshwj xeeb yuav tsum tau ua kom zoo nkauj sab hauv.

12. Cov txheej txheem dov txias / cov txheej txheem kos duab txias

Kev dov txias: Cov yeeb nkab hlau yog dov los ntawm cov dov ntawm lub tshuab dov txias, thiab qhov loj thiab ntev ntawm cov yeeb nkab hlau raug hloov pauv los ntawm kev hloov pauv txias tas mus li.

Kev kos duab txias: Cov yeeb nkab hlau yog flared thiab phab ntsa-txo nrog lub tshuab kos duab txias yam tsis muaj cua sov los hloov qhov loj thiab ntev ntawm cov yeeb nkab hlau. Cov yeeb nkab hlau kos duab txias muaj qhov tseeb siab thiab qhov chaw tiav zoo. Qhov tsis zoo yog tias qhov kev ntxhov siab seem yog loj, thiab cov yeeb nkab txias loj-txoj kab uas hla feem ntau siv, thiab cov khoom tiav lawm qhov ceev qeeb. Cov txheej txheem tshwj xeeb ntawm kev kos duab txias suav nrog:

① Lub taub hau vuam: Ua ntej kos duab txias, ib kawg ntawm cov yeeb nkab hlau yuav tsum tau mus rau (cov yeeb nkab hlau me me) lossis lub taub hau vuam (cov yeeb nkab hlau loj) los npaj rau cov txheej txheem kos duab, thiab me me ntawm cov yeeb nkab hlau tshwj xeeb yuav tsum tau cua sov thiab tom qab ntawd mus rau.

② Lubrication thiab ci: Ua ntej txias kos duab ntawm cov yeeb nkab hlau tom qab lub taub hau (vuam taub hau), lub qhov sab hauv thiab sab nraud ntawm cov yeeb nkab hlau yuav tsum tau lubricated, thiab cov yeeb nkab hlau coated nrog lubricant yuav tsum tau qhuav ua ntej txias kos duab.

③ Kev kos duab txias: Cov yeeb nkab hlau tom qab cov roj nplua nyeem qhuav nkag mus rau hauv cov txheej txheem kos duab txias, thiab cov khoom siv siv rau kev kos duab txias yog lub tshuab kos duab txias thiab lub tshuab kos duab txias hydraulic.

13. Kev Tshem Tawm Roj: Lub hom phiaj ntawm kev tshem tawm roj yog tshem tawm cov roj dov uas txuas rau sab hauv phab ntsa thiab sab nraud ntawm cov yeeb nkab hlau tom qab dov los ntawm kev yaug, yog li kom tsis txhob ua rau lub ntsej muag ntawm cov hlau puas tsuaj thaum lub sijhawm annealing thiab tiv thaiv cov pa roj carbon ntau ntxiv.

14. Kev kho cua sov: Kev kho cua sov rov qab kho cov duab ntawm cov khoom los ntawm kev rov ua dua thiab txo qhov kev tiv thaiv deformation ntawm cov hlau. Cov khoom siv kho cua sov yog lub cub tawg kho cua sov roj av.

15. Kev ntxuav cov khoom tiav lawm: Cov kav hlau tom qab txiav raug ntxuav kom huv si rau lub hom phiaj ntawm kev ua kom huv ntawm qhov chaw, yog li ntawd cov yeeb yaj kiab tiv thaiv oxide tuaj yeem tsim rau ntawm qhov chaw ntawm cov kav hlau thiab txhim kho kev ua tau zoo ntawm cov kav hlau.

16. Kev tshuaj xyuas cov khoom tiav lawm: Cov txheej txheem tseem ceeb ntawm kev tshuaj xyuas thiab kev sim cov khoom tiav lawm yog kev tshuaj xyuas meter → eddy probe → super probe → dej siab → cua siab. Kev tshuaj xyuas saum npoo av feem ntau yog los xyuas seb puas muaj qhov tsis zoo ntawm qhov chaw ntawm cov yeeb nkab hlau, seb qhov ntev ntawm cov yeeb nkab hlau thiab qhov loj ntawm phab ntsa sab nraud puas tsim nyog; qhov kev tshawb nrhiav eddy feem ntau siv lub tshuab ntes qhov tsis zoo eddy tam sim no los xyuas seb puas muaj qhov tsis zoo hauv cov yeeb nkab hlau; qhov kev tshawb nrhiav super feem ntau siv lub tshuab ntes qhov tsis zoo ultrasonic los xyuas seb cov yeeb nkab hlau puas tawg sab hauv lossis sab nraud; qhov dej siab, Cua siab yog siv lub tshuab hydraulic thiab cua siab los xyuas seb cov yeeb nkab hlau puas xau dej lossis cua, yog li kom ntseeg tau tias cov yeeb nkab hlau zoo.

17. Kev Ntim Khoom thiab Kev Khaws Cia: Cov kav hlau uas tau dhau qhov kev tshuaj xyuas nkag mus rau hauv thaj chaw ntim khoom tiav lawm rau kev ntim khoom. Cov ntaub ntawv siv rau kev ntim khoom suav nrog lub hau qhov, hnab yas, daim ntaub snakeskin, cov laug cam ntoo, cov siv hlau tsis xeb, thiab lwm yam. Sab nraud ntawm ob qho kawg ntawm cov kav hlau qhwv yog kab nrog cov laug cam ntoo me me, thiab sab nraud yog khi nrog cov siv hlau tsis xeb kom tiv thaiv kev sib cuag ntawm cov kav hlau thaum thauj mus los thiab ua rau muaj kev sib tsoo. Cov kav hlau ntim khoom nkag mus rau hauv thaj chaw ntim khoom tiav lawm.

Feem ntau cov ntim khoom yog liab qab, hlau xaim khi, muaj zog heev.

Yog tias koj muaj cov kev xav tau tshwj xeeb, koj tuaj yeem siv cov ntim khoom tsis xeb, thiab zoo nkauj dua.

Kev Thauj Mus Los:Qhia (Xa Khoom Qauv), Huab Cua, Tsheb Ciav Hlau, Av, Kev Thauj Khoom Hiav Txwv (FCL lossis LCL lossis Ntau)

Peb Cov Neeg Siv Khoom

Q: Puas yog lub chaw tsim khoom ua?

A: Yog, peb yog cov chaw tsim khoom. Peb muaj peb lub Hoobkas nyob hauv Tianjin City, Suav.

Q: Kuv puas tuaj yeem muaj kev txiav txim sim tsuas yog ob peb tons xwb?

A: Tau kawg. Peb tuaj yeem xa cov khoom thauj rau koj nrog LCL servivece. (Tsawg dua lub thawv thauj khoom)

Q: Yog tias cov qauv dawb?

A: Qauv pub dawb, tab sis tus neeg yuav khoom them rau cov khoom thauj.

Q: Koj puas yog tus neeg muag khoom kub thiab ua kev lag luam lav?

A: Peb xya xyoo tus neeg muag khoom kub thiab lees txais kev lees paub kev lag luam.