API 5L Gr. B Cov Yeeb Nkab Carbon Seamless

| Cov Qib | API 5L Qib B, X42, X52, X56, X60, X65, X70, X80 |

| Qib Kev Qhia Tshwj Xeeb | PSL1, PSL2 |

| Sab nraud txoj kab uas hla | 1/2" txog 2", 3", 4", 6", 8", 10", 12", 16", 18", 20", 24" txog 40". |

| Tuab Teem Caij | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, txog SCH 160 |

| Hom Kev Tsim Khoom | Seamless (Kub Dov thiab Txias Dov), Welded ERW (Hluav Taws Xob Tiv Thaiv Welded), SAW (Submerged Arc Welded) hauv LSAW, DSAW, SSAW, HSAW |

| Xaus Hom | Cov xaus beveled, Cov xaus tiaj tus |

| Qhov Ntev Ntau | SRL (Ib Leeg Random Ntev), DRL (Ob Chav Random Ntev), 20 FT (6 meters), 40FT (12 meters) lossis, kho kom haum |

| Cov kaus mom tiv thaiv | yas los yog hlau |

| Kev Kho Mob Nto | Ntuj, Varnished, Dub Pleev Xim, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad lossis Lined |

Cov yeeb nkab API 5L yog cov yeeb nkab hlau carbon uas siv rau hauv cov roj thiab cov roj xa mus. Nws kuj tseem siv los thauj lwm yam kua xws li pa dej, dej, thiab av nkos.

Cov lus qhia API 5L suav nrog ob hom kev tsim khoom welded thiab seamless.

Hom Welded: ERW, SAW, DSAW, LSAW, SSAW, HSAW Yeeb Nkab

Cov hom API 5L welded yeeb nkab feem ntau yog raws li nram no:

ERW: Kev vuam hluav taws xob tsis kam, feem ntau siv rau cov yeeb nkab txoj kab uas hla tsawg dua 24 ntiv tes.

DSAW/SAWKev vuam ob sab submerged arc/submerged arc welding, lwm txoj kev vuam rau ERW siv rau cov kav dej loj dua.

LSAWKev vuam siv txoj hlua khi hauv qab dej ntev, siv rau cov yeeb nkab uas muaj txoj kab uas hla mus txog 48 nti. Kuj tseem hu ua txheej txheem tsim khoom JCOE.

SSAW/HSAWKev vuam siv txoj hlua khi ua los ntawm kauv/kauv vuam siv txoj hlua khi ua los ntawm kauv, siv rau cov yeeb nkab uas muaj txoj kab uas hla txog li 100 nti.

Hom Yeeb Nkab Seamless: Cov yeeb nkab kub dov seamless dov txias

Cov yeeb nkab hlau seamless feem ntau yog siv rau cov yeeb nkab me me (feem ntau tsawg dua 24 nti).

(Cov yeeb nkab hlau tsis muaj qhov sib txuas yog qhov zoo dua li cov yeeb nkab vuam rau cov kab uas hla tsawg dua 150 hli (6 nti)).

Peb kuj ua cov yeeb nkab loj uas tsis muaj qhov txuas. Los ntawm kev siv cov txheej txheem kub dov, cov yeeb nkab tsis muaj qhov txuas uas muaj qhov txuas siab tshaj plaws ntawm 20 nti (508 hli) tuaj yeem tsim tau. Yog tias koj xav tau cov yeeb nkab tsis muaj qhov txuas uas muaj qhov txuas ntau dua 20", peb tuaj yeem tsim cov yeeb nkab tsis muaj qhov txuas los ntawm cov txheej txheem kub-nthuav dav nrog qhov txuas txog li 40 nti (1016 hli).

API 5L suav nrog cov qib xws li Qib B, X42, X46, X52, X56, X60, X65, X70 thiab X80.

API 5L Cov Yeeb Nkab Hlau muaj nyob rau hauv ntau qib hlau suav nrog Qib B, X42, X46, X52, X56, X60, X65, X70 thiab X80. Qib siab dua ntawm cov hlau, qhov nruj dua qhov kev tswj hwm sib npaug ntawm cov pa roj carbon thiab qhov siab dua ntawm cov khoom siv kho tshuab.

Ntxiv mus, cov tshuaj lom neeg ua ke ntawm cov kav dej API 5L uas tau welded thiab seamless nrog tib qib hlau muaj qhov sib txawv, uas cov kav dej welded muaj kev thov siab dua thiab cov ntsiab lus tsawg dua ntawm cov pa roj carbon thiab sulfur.

Cov Tshuaj Lom Zem rau PSL 1 yeeb nkab nrog t ≤ 0.984” | |||||||

| Qib Hlau | Feem pua ntawm pawg,% raws li kev tshuaj xyuas cua sov thiab khoom a, g | ||||||

| C | Mn | P | S | V | Nb | Ti | |

| siab tshaj plaws b | siab tshaj plaws b | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | |

| Cov Yeeb Nkab Seamless | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.28 | 1.2 | 0.03 | 0.03 | c, d | c, d | d |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| Cov Yeeb Nkab Welded | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.26 | 1.2 | 0.03 | 0.03 | c, d | c, d | d |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.26 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.26 e | 1.45 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.03 | 0.03 | f | f | f |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; thiab Mo ≤ 0.15%, | |||||||

| b. Rau txhua qhov kev txo qis ntawm 0.01% qis dua qhov siab tshaj plaws uas tau teev tseg rau cov pa roj carbon, kev nce ntawm 0.05% siab dua qhov siab tshaj plaws uas tau teev tseg rau Mn yog qhov tso cai, txog li ntawm 1.65% rau qib ≥ L245 lossis B, tab sis ≤ L360 lossis X52; txog li ntawm 1.75% rau qib > L360 lossis X52, tab sis < L485 lossis X70; thiab txog li ntawm 2.00% rau qib L485 lossis X70., | |||||||

| c. Tshwj tsis yog tias pom zoo lwm yam NB + V ≤ 0.06%, | |||||||

| d. Nb + V + TI ≤ 0.15%, | |||||||

| e. Tshwj tsis yog tias tau pom zoo lwm yam., | |||||||

| f. Tshwj tsis yog tias pom zoo lwm yam, NB + V = Ti ≤ 0.15%, | |||||||

| g. Tsis pub ntxiv B ntxiv thiab B seem ≤ 0.001% | |||||||

| Cov Tshuaj Lom Zem rau PSL 2 yeeb nkab nrog t ≤ 0.984” | |||||||||||||||||||||

| Qib Hlau | Feem pua ntawm pawg,% raws li kev tshuaj xyuas cua sov thiab khoom | Carbon Equiv a | |||||||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | Lwm yam | CE IIW | CE Pcm | |||||||||||

| siab tshaj plaws b | siab tshaj plaws | siab tshaj plaws b | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | siab tshaj plaws | ||||||||||||

| Cov Yeeb Nkab Seamless thiab Welded | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g, h, l | Raws li tau pom zoo | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | kuv,j | Raws li tau pom zoo | |||||||||||

| X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Raws li tau pom zoo | |||||||||||

| X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Raws li tau pom zoo | |||||||||||

| Cov Yeeb Nkab Welded | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | kuv,j | .043f | 0.25 | ||||||||||

| X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | kuv,j | – | 0.25 | ||||||||||

| X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | kuv,j | – | 0.25 | ||||||||||

| a. SMLS t>0.787”, CE cov kev txwv yuav tsum yog raws li tau pom zoo. Cov kev txwv CEIIW siv rau fi C> 0.12% thiab cov kev txwv CEPcm siv rau yog tias C ≤ 0.12%, | |||||||||||||||||||||

| b. Rau txhua qhov kev txo qis ntawm 0.01% qis dua qhov siab tshaj plaws rau C, kev nce ntawm 0.05% siab dua qhov siab tshaj plaws rau Mn yog tso cai, txog li ntawm 1.65% rau qib ≥ L245 lossis B, tab sis ≤ L360 lossis X52; txog li ntawm 1.75% rau qib > L360 lossis X52, tab sis < L485 lossis X70; txog li ntawm 2.00% rau qib ≥ L485 lossis X70, tab sis ≤ L555 lossis X80; thiab txog li ntawm 2.20% rau qib > L555 lossis X80., | |||||||||||||||||||||

| c. Tshwj tsis yog tias tau pom zoo lwm yam Nb = V ≤ 0.06%, | |||||||||||||||||||||

| d. Nb = V = Ti ≤ 0.15%, | |||||||||||||||||||||

| e. Tshwj tsis yog tias pom zoo, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% thiab Mo ≤ 0.15%, | |||||||||||||||||||||

| f. Tshwj tsis yog tias tau pom zoo lwm yam, | |||||||||||||||||||||

| g. Tshwj tsis yog tias tau pom zoo lwm yam, Nb + V + Ti ≤ 0.15%, | |||||||||||||||||||||

| h. Tshwj tsis yog tias pom zoo, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% thiab MO ≤ 0.50%, | |||||||||||||||||||||

| i. Tshwj tsis yog tias pom zoo, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% thiab MO ≤ 0.50%, | |||||||||||||||||||||

| j. B ≤ 0.004%, | |||||||||||||||||||||

| k. Tshwj tsis yog tias pom zoo, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% thiab MO ≤ 0.80%, | |||||||||||||||||||||

| l. Rau txhua qib yeeb nkab PSL 2 tshwj tsis yog cov qib uas muaj cov lus hauv qab j sau tseg, cov hauv qab no siv tau. Tshwj tsis yog tias pom zoo lwm yam tsis pub ntxiv B thiab seem B ≤ 0.001%. | |||||||||||||||||||||

| PSL | Kev Xa Khoom | Qib yeeb nkab |

| PSL1 | Raws li dov, normalized, normalizing tsim | A |

| Raws li dov, normalizing dov, thermomechanical dov, thermo-mechanical tsim, normalizing tsim, normalized, normalized thiab tempered lossis yog tias pom zoo Q&T SMLS xwb | B | |

| Raws li dov, normalizing dov, thermomechanical dov, thermo-mechanical tsim, normalizing tsim, normalized, normalized thiab tempered | X42, X46, X52, X56, X60, X65, X70 | |

| PSL 2 | Raws li dov | BR, X42R |

| Normalizing dov, normalizing tsim, normalized lossis normalized thiab tempered | BN, X42N, X46N, X52N, X56N, X60N | |

| Txias thiab tempered | BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| Thermomechanical dov los yog thermomechanical tsim | BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| Thermomechanical dov | X90M, X100M, X120M | |

| Qhov txaus (R, N, Q lossis M) rau PSL2 qib, yog rau qib hlau |

PSL yog luv rau Product Specification Level thiab muaj PSL1 thiab PSL2. Nws zoo li qib zoo.

PSL1 thiab PSL2 tsis yog tsuas yog sib txawv hauv kev sim xwb, tab sis kuj tseem muaj cov tshuaj lom neeg thiab cov khoom siv kho tshuab.

PSL2 nruj dua li PSL1 txog cov tshuaj lom neeg sib xyaw, cov khoom tensile, kev sim cuam tshuam, kev sim tsis ua puas tsuaj, thiab lwm yam.

Kev Ntsuas Kev Cuam Tshuam

Kev ntsuam xyuas kev cuam tshuam - Tsis tas yuav tsum muaj rau PSL1, tab sis yog rau PSL2 (tshwj tsis yog X80).

Kev Ntsuas Tsis Ua Rau Puas Tsuaj

PSL1 tsis xav tau kev sim tsis ua puas tsuaj tab sis PSL2 ua li ntawd.

(Kev sim tsis puas tsuaj: Kev sim thiab kev sim tsis puas tsuaj hauv tus qauv API 5L siv cov duab xoo hluav taws xob, ultrasonic, lossis lwm txoj kev (tsis rhuav tshem cov khoom) los nrhiav cov qhov tsis zoo thiab qhov tsis zoo hauv cov kav dej.)

Kev ntim khoom yogfeem ntau liab qab, hlau xaim khi, heevmuaj zog.

Yog tias koj muaj cov kev xav tau tshwj xeeb, koj tuaj yeem sivkev ntim khoom tsis xeb, thiab zoo nkauj dua.

Cov kev ceev faj rau kev ntim khoom thiab kev thauj mus los ntawm cov kav hlau carbon

1.API 5L Cov Yeeb Nkab Hlauyuav tsum tau tiv thaiv los ntawm kev puas tsuaj los ntawm kev sib tsoo, extrusion thiab txiav thaum lub sijhawm thauj mus los, khaws cia thiab siv.

2. Thaum siv cov kav hlau carbon, koj yuav tsum ua raws li cov txheej txheem kev nyab xeeb thiab xyuam xim kom tiv thaiv kev tawg, hluav taws, lom thiab lwm yam xwm txheej.

3. Thaum siv,Cov hlau carbon API 5L Yeeb Nkabyuav tsum tsis txhob kov cov khoom kub thiab txias, cov khoom siv corrosive, thiab lwm yam. Yog tias siv rau hauv cov chaw ib puag ncig no, cov kav hlau carbon ua los ntawm cov khoom siv tshwj xeeb xws li kev tiv taus kub thiab kev tiv taus corrosion yuav tsum tau xaiv.

4. Thaum xaiv cov kav hlau carbon, cov kav hlau carbon ntawm cov ntaub ntawv tsim nyog thiab cov lus qhia yuav tsum tau xaiv raws li kev txiav txim siab dav dav xws li kev siv ib puag ncig, cov khoom nruab nrab, siab, kub thiab lwm yam.

5. Ua ntej siv cov kav hlau carbon, yuav tsum tau kuaj xyuas thiab sim kom paub tseeb tias lawv qhov zoo ua tau raws li qhov yuav tsum tau ua.

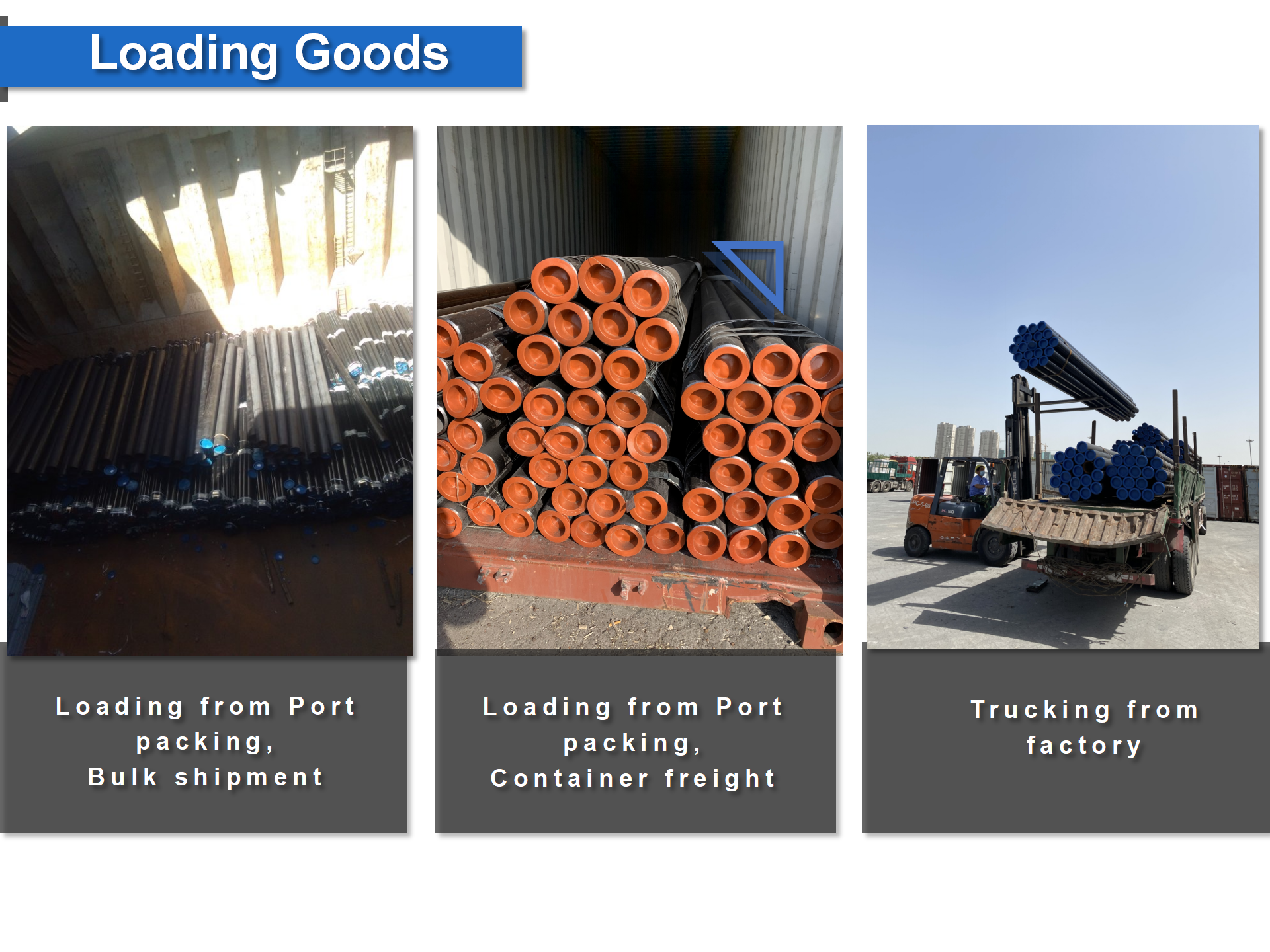

Kev Thauj Mus Los:Kev Xa Khoom Sai (Xa Khoom Qauv), Huab Cua, Tsheb Ciav Hlau, Av, Kev Thauj Khoom Hiav Txwv (FCL los yog LCL los yog ntau)

Q: Puas yog lub chaw tsim khoom ua?

A: Yog, peb yog cov chaw tsim khoom siv raj hlau uas nyob hauv lub zos Daqiuzhuang, lub nroog Tianjin, Suav teb.

Q: Kuv puas tuaj yeem muaj kev txiav txim sim tsuas yog ob peb tons xwb?

A: Tau kawg. Peb tuaj yeem xa cov khoom thauj rau koj nrog LCL servivece. (Tsawg dua lub thawv thauj khoom)

Q: Yog tias cov qauv dawb?

A: Qauv pub dawb, tab sis tus neeg yuav khoom them rau cov khoom thauj.

Q: Koj puas yog tus neeg muag khoom kub thiab ua kev lag luam lav?

A: Peb muaj 13 xyoos kev muag khoom kub thiab lees txais kev lees paub kev lag luam.