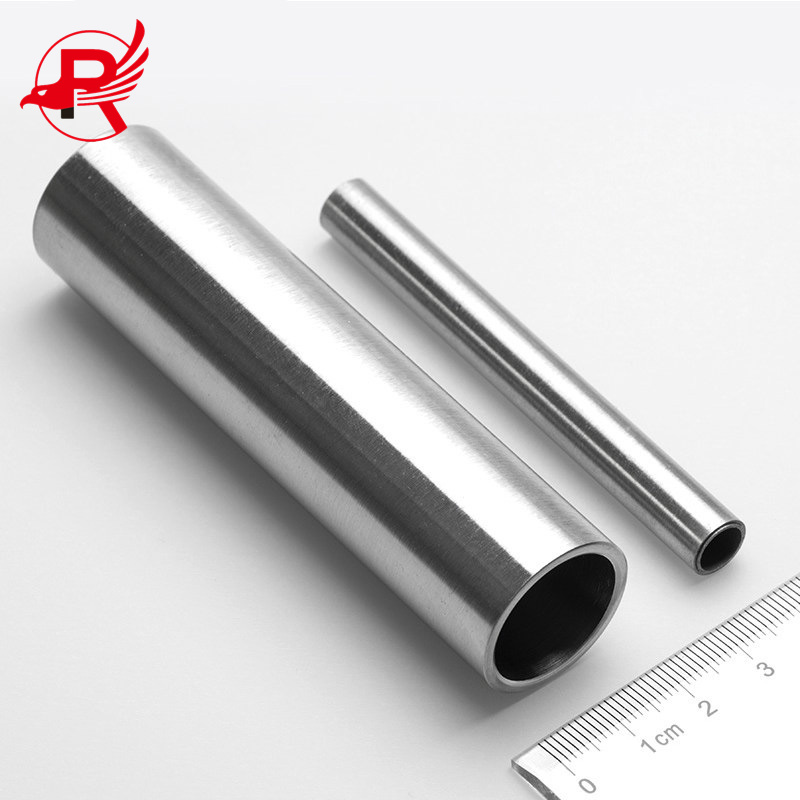

1 hli 2 hli Zoo 410 420 430 440 Cov Yeeb Nkab Hlau Stainless SS Tube

| tem | 410 420 430 440 Cov Yeeb Nkab Hlau Tsis Muaj Hlau |

| Tus Qauv | JIS, AiSi, ASTM, GB, DIN, EN |

| Qhov chaw keeb kwm | Tuam Tshoj |

| Lub Npe Hom | ROYAL |

| Hom | Seamless / Weld |

| Qib Hlau | 200/300/400 Series, 904L S32205 (2205), S32750 (2507) |

| Daim Ntawv Thov | Kev lag luam tshuaj lom neeg, cov khoom siv kho tshuab |

| Kev Pabcuam Ua Haujlwm | Khoov, Vuam, Decoiling, Xuas Nrig, Txiav, Moulding |

| Kev siv tshuab | Kub dov / txias dov |

| Cov nqe lus them nqi | T/T (30% TSO NYIAJ) |

| Lub Sijhawm Nqe | CIF CFR FOB EX-WORK |

Cov yeeb nkab hlau tsis xeb yog ib hom hlau hollow ntev puag ncig, uas feem ntau yog siv rau hauv cov kav dej thauj mus los hauv kev lag luam xws li roj av, kev lag luam tshuaj lom neeg, kev kho mob, khoom noj khoom haus, kev lag luam sib zog, cov cuab yeej siv tshuab, thiab lwm yam, nrog rau cov khoom siv kho tshuab. Tsis tas li ntawd, thaum lub zog khoov thiab torsional zoo ib yam, qhov hnyav sib dua, yog li nws kuj siv dav hauv kev tsim cov khoom siv kho tshuab thiab cov qauv tsim kho. Kuj tseem siv ua rooj tog thiab khoom siv hauv chav ua noj, thiab lwm yam.

Lus Cim:

1. Kev kuaj dawb, 100% kev lees paub zoo tom qab muag, Txhawb nqa txhua txoj kev them nqi;

2. Tag nrho lwm yam lus qhia ntawm cov kav dej hlau carbon puag ncig muaj raws li koj xav tau (OEM & ODM)! Tus nqi Hoobkas koj yuav tau txais los ntawm ROYAL GROUP.

Cov Tshuaj Lom Zem ntawm Cov Yeeb Nkab Hlau Stainless

| Cov Tshuaj Muaj pes tsawg leeg% | ||||||||

| Qib | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 | ≤0.75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0.15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0.15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0.07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0. 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Los ntawm ntau txoj kev ua tiav ntawm kev dov txias thiab kev ua tiav ntawm qhov chaw tom qab dov, qhov chaw tiav ntawm cov hlau tsis xeblub bars muaj peev xwm muaj ntau hom sib txawv.

Muaj ntau hom kev kho qhov chaw rau cov yeeb nkab hlau tsis xeb, txhua tus muaj nws tus yam ntxwv thiab qhov zoo tshwj xeeb.

Ib qho ntawm cov hom kev kho qhov chaw rau cov yeeb nkab stainless hlau uas siv ntau tshaj plaws yog kev kho 2B. Kev kho qhov chaw no yog ua tiav los ntawm kev dov txias ntawm daim ntawv stainless hlau thiab tom qab ntawd annealing nws. Qhov chaw ua tiav muaj qhov tiav du, matte, zoo tagnrho rau cov ntawv thov uas qhov zoo nkauj tsis yog qhov teeb meem tseem ceeb.

Lwm qhov kev ua tiav nrov rau cov yeeb nkab hlau tsis xeb yog qhov ua tiav brushed. Qhov kev ua tiav no yog ua tiav los ntawm kev siv txhuam hlau los tsim cov kab ntsug lossis kab rov tav ntawm qhov chaw ntawm cov yeeb nkab hlau tsis xeb. Cov tiav brushed feem ntau siv rau hauv cov ntawv thov uas qhov zoo nkauj yog qhov tseem ceeb, xws li kev siv vaj tsev lossis kho kom zoo nkauj. Ntxiv rau 2B thiab kev kho qhov chaw brushed, cov yeeb nkab hlau tsis xeb kuj muaj lwm hom kev kho qhov chaw, xws li kev kho qhov chaw BA thiab kev kho qhov chaw iav.

Qhov BA tiav yog ua tiav los ntawm kev ua kom cov hlau tsis xeb ci ntsa iab, ua rau qhov chaw tiav zoo li daim iav. Qhov cuam tshuam iav yog ua tiav los ntawm kev txhuam qhov chaw hlau tsis xeb kom ci ntsa iab, ua rau pom zoo li daim iav.

Qhov kev xaiv ntawm qhov chaw tiav rau cov yeeb nkab hlau tsis xeb nyob ntawm ntau yam xws li daim ntawv thov, ib puag ncig, thiab qhov zoo nkauj xav tau. Piv txwv li, qhov tiav 2B yuav tsim nyog rau cov ntawv thov kev lag luam uas qhov zoo nkauj tsis yog qhov tseem ceeb, thaum qhov tiav txhuam lossis daim iav yuav tsim nyog rau kev siv vaj tse lossis kho kom zoo nkauj. Hauv kev xaus, qhov tiav ntawm qhov chaw tiav ntawm cov yeeb nkab hlau tsis xeb yog ib qho tseem ceeb uas cuam tshuam rau nws qhov kev ua tau zoo thiab kev ua haujlwm ntev.

Kev kho kom zoo nkauj ntawm qhov chaw sib txawv muaj cov yam ntxwv thiab cov txiaj ntsig sib txawv nyob ntawm seb daim ntawv thov thiab qhov zoo nkauj uas xav tau. Cov yeeb nkab hlau tsis xeb tseem yog cov khoom siv nrov hauv ntau yam lag luam, thiab nws qhov tiav ntawm qhov chaw ua lub luag haujlwm tseem ceeb hauv nws txoj kev vam meej.

Cov txheej txheem tseem ceeb: cov hlau puag ncig → rov tshuaj xyuas → tev tawv → blanking → centering → cua sov → perforation → pickling → lub taub hau tiaj tus → tshuaj xyuas thiab sib tsoo → txias dov (txias kos duab) → degreasing → kho cua sov → ncaj → txiav yeeb nkab (ruaj khov-rau-ntev) → pickling / passivation → tiav cov khoom tshuaj xyuas (eddy tam sim no, ultrasonic, dej siab) → ntim khoom thiab khaws cia.

Kauj ruam thawj zaug hauv kev tsim khoom ntawmcov kav hlau tsis xebyog kev xaiv cov khoom siv raw. Cov hlau tsis xeb muaj hlau, chromium, thiab ntau yam hlau xws li nickel, molybdenum, lossis titanium. Nws yog ib qho tseem ceeb uas yuav tsum xaiv cov khoom siv raw zoo kom ntseeg tau tias qhov zoo tshaj plaws thiab cov yam ntxwv ntawm cov khoom tiav.

Thaum xaiv cov khoom siv raw lawm, kauj ruam tom ntej hauv cov txheej txheem tsim khoom yog yaj cov hlau hauv lub cub tawg. Tom qab ntawd cov hlau uas yaj lawm raug nchuav rau hauv pwm kom ua ib daim hlau billet khov.

Tom qab ntawd, cov hlau billet raug xa mus rau lub tshuab dov kub uas nws raug tsim los ua cov duab xav tau. Cov hlau dov kub tom qab ntawd raug rau kev kho cua sov ntxiv, xws li annealing lossis quenching, kom txhim kho nws cov khoom. Annealing suav nrog kev ua kom cov hlau kub rau qhov kub siab thiab tom qab ntawd txias nws qeeb qeeb kom ua rau nws mos dua thiab ductile dua. Quenching suav nrog kev txias sai sai hlau kom tempered nws thiab ua rau nws muaj zog dua.

Cov kauj ruam tom ntej hauv kev tsim khoom yog machining.Cov kav hlau tsis xebraug tshuab kom txog thaum kawg nws cov duab, qhov loj me thiab qhov ntev siv ntau yam cuab yeej suav nrog lathes, milling tshuab thiab laum.

Cov txheej txheem machining kuj tseem yuav suav nrog kev tshem tawm txhua qhov tsis zoo ntawm qhov chaw xws li roughness lossis burrs. Tom qab cov txheej txheem machining, cov kav dej stainless hlau raug ntxuav kom tshem tawm txhua yam kev ua qias tuaj ua ntej xa mus rau kev tshuaj xyuas. Qhov no yog ib kauj ruam tseem ceeb hauv kev ua kom ntseeg tau tias cov khoom tiav ua tau raws li cov lus qhia thiab cov qauv zoo.

Cov txheej txheem sim suav nrog kev sim siab, kev sim cov khoom sib nqus, kev sim ultrasonic thiab lwm yam kev sim. Thaum kawg, cov yeeb nkab hlau tsis xeb tiav lawm thiab npaj txhij rau kev xa khoom lossis kev teeb tsa.

Cov kav dej tuaj yeem muab ntau yam kev kho mob saum npoo xws li polishing, sib tsoo lossis electropolishing kom txhim kho lawv cov tsos thiab tiv taus corrosion.

Xaus lus, cov txheej txheem tsim cov yeeb nkab hlau tsis xeb yog qhov nyuaj thiab xav tau kev txawj ntse thiab kev saib xyuas kom meej. Txawm li cas los xij, qhov zoo ntawm cov yeeb nkab hlau tsis xeb ua rau nws yog cov khoom siv nrov hauv ntau yam lag luam. Cov txheej txheem ntawm kev xaiv cov khoom siv raw zoo, yaj, casting, dov, kho cua sov, machining, tshuaj xyuas thiab ua tiav ua rau cov khoom ruaj khov, tiv taus xeb uas tuaj yeem tiv taus cov xwm txheej hnyav thiab muab kev pabcuam txhim khu kev qha ntau xyoo.

Feem ntau cov ntim khoom yog liab qab, hlau xaim khi, muaj zog heev.

Yog tias koj muaj cov kev xav tau tshwj xeeb, koj tuaj yeem siv cov ntim khoom tsis xeb, thiab zoo nkauj dua.

Kev Thauj Mus Los:Qhia (Xa Khoom Qauv), Huab Cua, Tsheb Ciav Hlau, Av, Kev Thauj Khoom Hiav Txwv (FCL lossis LCL lossis Ntau)

Peb Cov Neeg Siv Khoom

Q: Puas yog lub chaw tsim khoom ua?

A: Yog, peb yog cov chaw tsim khoom. Peb muaj peb lub Hoobkas nyob hauv Tianjin City, Suav.

Q: Kuv puas tuaj yeem muaj kev txiav txim sim tsuas yog ob peb tons xwb?

A: Tau kawg. Peb tuaj yeem xa cov khoom thauj rau koj nrog LCL servivece. (Tsawg dua lub thawv thauj khoom)

Q: Yog tias cov qauv dawb?

A: Qauv pub dawb, tab sis tus neeg yuav khoom them rau cov khoom thauj.

Q: Koj puas yog tus neeg muag khoom kub thiab ua kev lag luam lav?

A: Peb xya xyoo tus neeg muag khoom kub thiab lees txais kev lees paub kev lag luam.